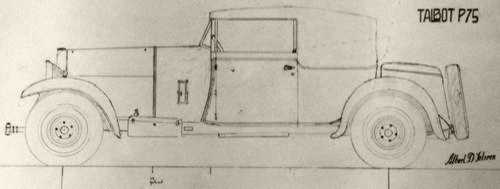

Regarding the body in general, there is so little left, that I decided to recreate the body completely.

It is a design D’Ieteren used on different chassis like Minervas, Voisins…

I particulary like the fiacre style combined with that amazing three-part windshield. This is a long chassis, so it looks quite elegant with it’s aluminium wheelcaps.

The fiacre style has only been used in the short timeframe between 1928 and 1931, when the streamlined bodies emerged.

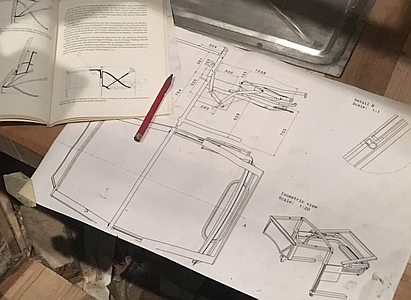

I made some technical drawings including details etc. to have proper measurements, and figure out the convertible mechanism.

Wood will be ash. I do have a very good soure for long dried ash. Not fast kiln dried, but kept under sun and snow for years. I used that for the Mercedes, and the cut wood does not deflect at all once cut! Perfect.

Some Housebuilding (8/2015)

Here the first pile of wood. These are 5m long ash planks 52, 37 and 22mm thick. For thicker parts I do have some stock left over from the Mercedes project.

I made templates of the pieces I need to lay them out on the wood, so that the curved parts fit the natural grain.

Then I cut them with a bandsaw, planed them mostly by hand because it gives a much finer surface than machine planing.

To cut the slots for the joints I usually use a circular saw for rough cuts and finish them with very very sharp chisels.

For me, this is the most beautiful work in the world transforming a rough plank into nice and smooth pieces with perfect lines. So I’ll take my time, not that its over too fast 🙂

I started as usual building a straight frame based on the centerline of the chassis.

Amazing, once you measure in detail how crooked the crossmembers have been riveted in. There is a difference of 5mm left to right.

Of course everything is connected by tongue and groove, glued together and hold together with cross drilled wooden dowel pins.

Still continuing sawing, planing, milling the ash. Huge piles of shaves, sawdust all over the place! I clean up every week, but everything- really everything (!) is covered with fine and coarse sawdust. Once the wood part is finished, it will take quite a while to clean up.

It’s middle of September, days are becoming shorter, and its getting colder. I do have to hurry up, as long as it is not too cold to glue. I want to finish at least the front section.

This is a description of the last piece of wood: The lower edge of the center winshield. The front is pretty complicated due to the panoramic window. I started with the A-column braced it towards the bulkhead.

The two angled pieces desribe the lower edge of the small side windows of the windshield.

Every piece is layed out starting with a simple hardboard template:

This is then transferred to the plank and cut out with a circular saw roughly.

After that I use my electric planer to shape it exacly to the desired shape. Still rectangular.

To create the technical necessary shapes I cut the edges with a handheld router.

Then it needs to be connected via tongue and groove to the corresponding woods.

This was pretty complex because all edges are in some sort of an an angle: 13° for the windshield, 45° for the sides, an the tongues in anther angle following the grain of the wood.

This is done by hand with saw and chisel. Extremly sharp to shave off material just by hand where required.

Its then glued together still with some extra material and once cured sanded smooth. One have to be very very careful, because it’s not so easy to plane on new wood…

The wood is finished and protected with Owatrol oil.

Then the metal brace is newly rust protected and properly painted.

Once these braces are in place, the front is pretty rigid. -Voila:

Long time no news as I was travelling by boat in 2017- still constantly tinkering on my project. In this manner I manufactured the rest of the body framing. The rear quarters are not so simple because of the complex curves.

Convertible Top 2018

To design and manufacture is quite a complex process.

For designing there is an excellent ressource from the German national Museum (Deutsches Museum) as they have annual reports and there was one from 1981 where Adolf Lehman describes convertible tops, their folding mechnism and all details in 76 pages.

(ISBN 3.486-25381-6 only available used).

This is what I used as a start to design it in CAD with all the kinematics.

So the simple part remaing is to build it in real metal and wood, et voici:

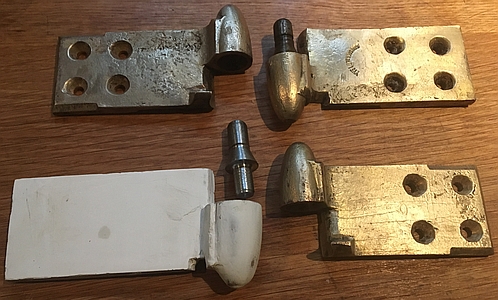

Doors 11/2018

The last remaing part are the door frames. I had some hinge parts from one side. So I had to build a mirrored mould pattern which is about 4% bigger and had the remaining cast in brass. With some machining they came out pretty nice.

The frames itself is business as usual.

Next will be the panel beating…